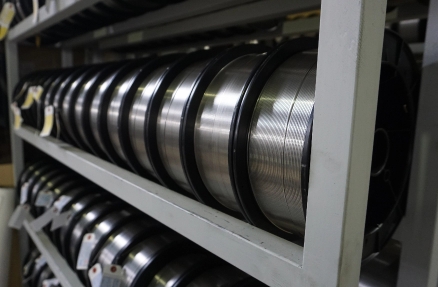

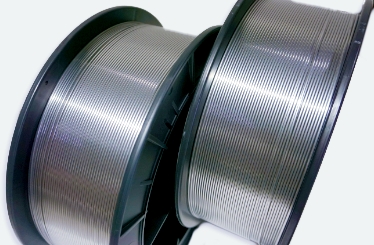

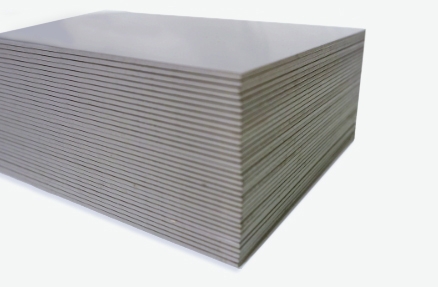

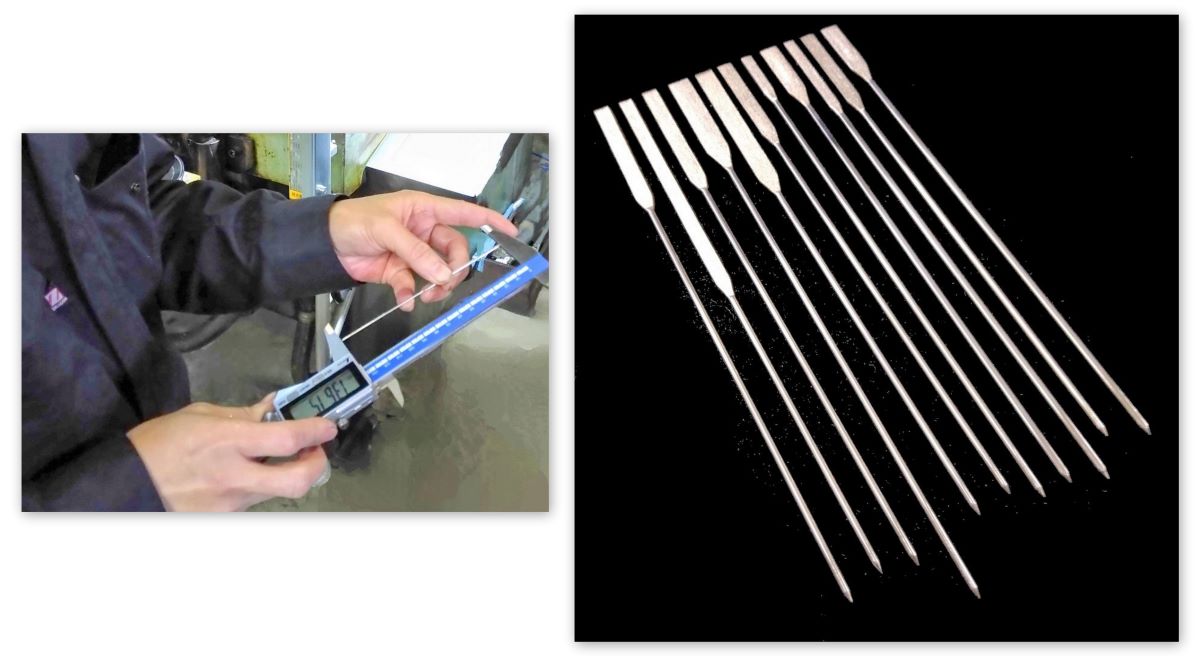

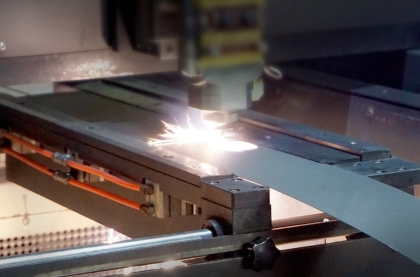

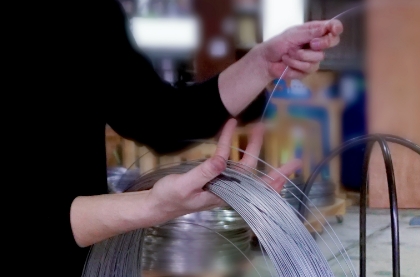

The technology we have cultivated,

world-class level manufacturing.

The processing of titanium requires high technology and deep knowledge. Skilled craftspeople who have improved their skills through the integrated production at our factory, challenge all possibilities and give form to customer requests.